Lean and Agile Methods

Lean and Agile Methods

As a leading thought leader in Lean and Agile methods that combine the fields of Complexity Thinking, Distributed Leadership, and Team Science, Thurlow is responsible for many new theories, innovative practices, and effective approaches to solving your transformational challenges. He has worked alongside the co-creators of Scrum, as well as signatories of the Agile Manifesto. He has helped develop and test many techniques to scale agile ways of working, and has successfully combined leading practices into assemblages (interconnected relationships of component parts) that enable greater utility that the practices used standalone.

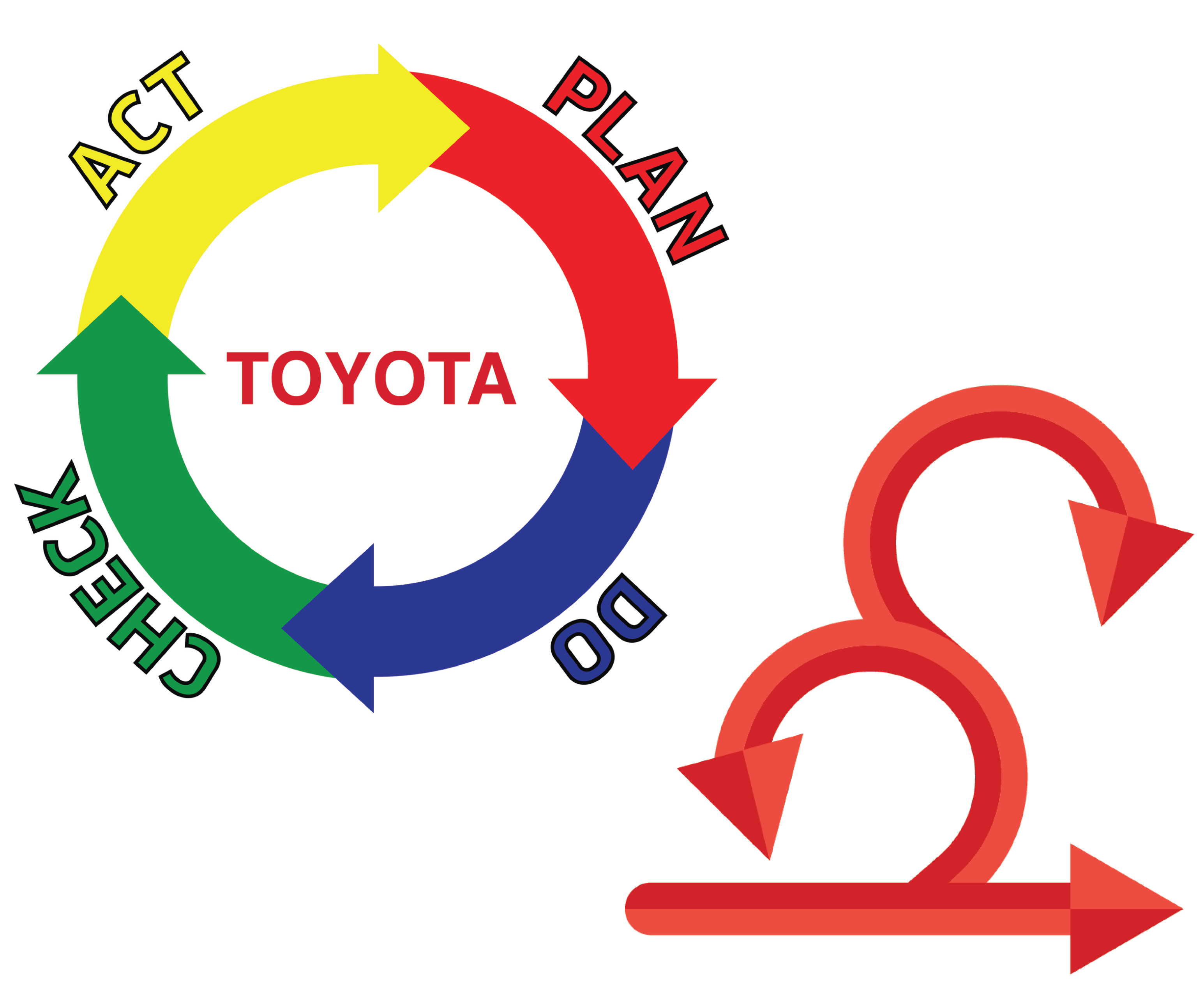

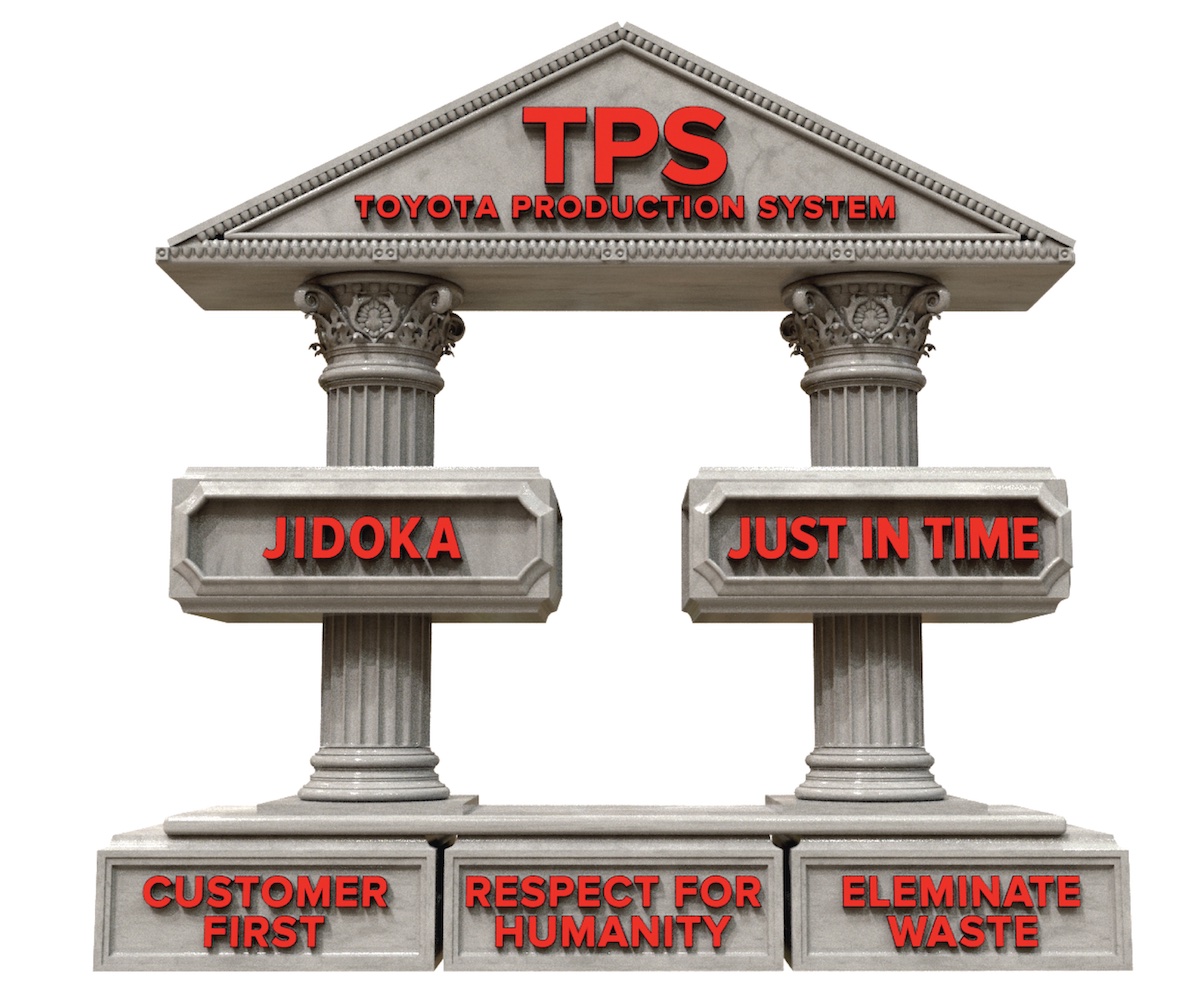

Scrum the Toyota Way

This is the World Agility Forum award winning class that was designed by Nigel Thurlow, delivered globally across Toyota, and that showed them how to apply Scrum alongside the Toyota Production System. This is the class that trained Toyota!

As one of the most successful practices in history, Toyota is well known for creating the Toyota Production System and establishing the “Toyota Way” culture. “Scrum The Toyota Way” effectively combines the capabilities of the Toyota Production System with the simplicity and power of Scrum. It brings together Systems Thinking and Complexity Thinking while also bridging Lean and Agile disciplines in a unique way.

Scaling Agility through Organizational Design

Thurlow was one of the early architects of Scrum at Scale and was responsible for prototyping the Product Owner Metascrum pattern while at 3M. This is now integral to that scaling approach. However, there is no one size fits all approach, and no magical framework for scaling Scrum or Agile. Without a deep understanding of the problems that need to be solved to enable true organizational agility and lean optimization, simply throwing tools and techniques at the organization will yield limited results.

Thurlow engages at all levels of the organization to leverage your team resources in identifying the real changes that are needed to achieve the desired outcomes. Many of the approaches described on this site form part of the toolkit that he uses, but by no means is this an exhaustive list. Every client and every context is different, and within every client multiple contexts exist. There are some standard approaches that are used in every engagement, but then there are many approaches that are combined to find the right approach in each context. This is the Triple Helix concept he created as part of his work on The Flow System.

The Flow System

The Flow System, is a system of learning and understanding for dealing with complexity. For the first time in this field, The Flow System offers an assemblage of methods through the Triple Helix of Flow (Complexity Thinking, Distributed Leadership, Team Science).

Assemblages provide several potential methods that can be combined to aid in navigating complexity. This coming together of methods varies by context and is counter to the concept of universality (one size fits all approach).

The coming together of these methods is more important than the methods themselves because an assemblage of methods need to interconnect with one another. The Flow System provides a ‘coming together’ of several methods to better address ambiguity, complexity, and uncertainty. The DNA of Organizations.

Assemblages are not viewed as having parts and wholes and are defined solely by their external relations of composition, mixture, and aggregation.

Visual Management and Problem Identification

Thurlow offers a range of practical tools derived from his work with Toyota, and these include Value Stream Mapping. Whenever there is a product for a customer, there is a value stream. The challenge lies in seeing it.

Toyota developed this approach and internally it is known as Material and Information Flow Diagramming or Mapping. It is a simple way to visualize how we do what we do; how we create value. Value stream mapping looks at 3 dimensions, people, products/objects, and information. As mentioned in the overview in this document the flow of information is critical in reducing costs, improving quality, and reduction in lead times. In short, the flow of value.

A VSM workshop simply brings together people who are deeply knowledgeable about the products and the process of how the products (value) are created. The outcome of any session, or series of sessions, is to identify constraints in the system and target actions to eliminate or mitigate them. A constraint is not simply a bottleneck but “anything that prevents the system from achieving a better performance measure towards its goal”. A further outcome is to design a better value stream.

Visualizing the Flow of Value

Flow of value is not achieved through local optimizations, which is often the target of lean kaizen blitzes or 6Sigma kaizen events, considered an anathema to flow. You must view a system as a whole, and this means beyond those who do the actual technical work or construction tasks.

An organizational system involves many discrete and dependent elements, such as HR, Procurement, Vendor Management, Legal, Compliance etc., and many external service providers. These are all part of the value stream. How they interact and collaborate is crucial to optimizing flow. Understanding precisely how they do this, is where you start.

VSM is a fundamental Lean technique and is just the beginning. It provides no solutions, simply revealing system constraints that require attention. It is an essential technique in learning to see. You can’t fix what you can’t see.